stamping parts knowledge

Views : 1009

Author : Susan

Update time : 2021-01-06 16:13:33

Metal stamping parts are made of stainless steel, iron, aluminum, copper and other plates and heterosexual materials by punching and moulds at room temperature to make them deform or fracture, so as to form the required specified shape products.

Metal stamping parts processing technology includes blanking, bending, deep drawing, forming, finishing and other processes.

The main characteristics of metal stamping parts

1. Metal stamping parts are made by stamping under the premise of small material consumption. Its parts are light in weight and have good stiffness.

2. Hardware stamping parts have high dimensional accuracy, uniform and consistent with the size of the die parts, and good interchangeability.

No further machining is required to meet the general assembly and use requirements.

3. In the process of stamping, because the surface of the material is not damaged, it has a good surface quality, smooth and beautiful appearance, which provides convenient conditions for surface painting, electroplating, phosphating and other surface treatment.

Notes on safety production of metal stamping parts

1. Install protective devices.

In the production of metal stamping parts, stamping equipment must be installed with safety protection device, to prevent the accident caused by operating errors.

Various protective devices have their own characteristics and use range, improper use will still happen injury accidents.

Therefore, it is necessary to make clear the role of various protective devices, in order to achieve correct use, to ensure safe operation.

2, improve stamping equipment, improve the efficiency and safety of production.

Now many enterprises use or old hardware stamping equipment control system, on the efficiency and accuracy level much lower than the current market requirements, and because the electric control system of the old there are many unsafe factors, in order to assure the most effective use of metal stamping parts production and precision and the safety of the operation, we should to update replacement and improvement of stamping equipment, improve production efficiency and safety.

3, improve the manufacturing process, to achieve the manual mold outside the operation.

For mass production operations, we can start from the reform of the process and mold to realize mechanization and automation.

Such as the use of automation, multi-station stamping machinery and equipment, the use of multi-tool and mechanized into the production device, the use of continuous die, composite die and other combined process measures.

Metal stamping parts processing technology includes blanking, bending, deep drawing, forming, finishing and other processes.

The main characteristics of metal stamping parts

1. Metal stamping parts are made by stamping under the premise of small material consumption. Its parts are light in weight and have good stiffness.

2. Hardware stamping parts have high dimensional accuracy, uniform and consistent with the size of the die parts, and good interchangeability.

No further machining is required to meet the general assembly and use requirements.

3. In the process of stamping, because the surface of the material is not damaged, it has a good surface quality, smooth and beautiful appearance, which provides convenient conditions for surface painting, electroplating, phosphating and other surface treatment.

Notes on safety production of metal stamping parts

1. Install protective devices.

In the production of metal stamping parts, stamping equipment must be installed with safety protection device, to prevent the accident caused by operating errors.

Various protective devices have their own characteristics and use range, improper use will still happen injury accidents.

Therefore, it is necessary to make clear the role of various protective devices, in order to achieve correct use, to ensure safe operation.

2, improve stamping equipment, improve the efficiency and safety of production.

Now many enterprises use or old hardware stamping equipment control system, on the efficiency and accuracy level much lower than the current market requirements, and because the electric control system of the old there are many unsafe factors, in order to assure the most effective use of metal stamping parts production and precision and the safety of the operation, we should to update replacement and improvement of stamping equipment, improve production efficiency and safety.

3, improve the manufacturing process, to achieve the manual mold outside the operation.

For mass production operations, we can start from the reform of the process and mold to realize mechanization and automation.

Such as the use of automation, multi-station stamping machinery and equipment, the use of multi-tool and mechanized into the production device, the use of continuous die, composite die and other combined process measures.

Related News

Read More >>

Huiding Hardware successfully participated in the Russian Industrial Exhibition

Huiding Hardware successfully participated in the Russian Industrial Exhibition

Jul .21.2023

Huiding Hardware had participated in the industrial exhibition in Yekaterinburg, Russia from July 10th to 13th, 2023. The main exhibited products include buckles, clamps, hinges, handles, indexing pins, and stamping parts.

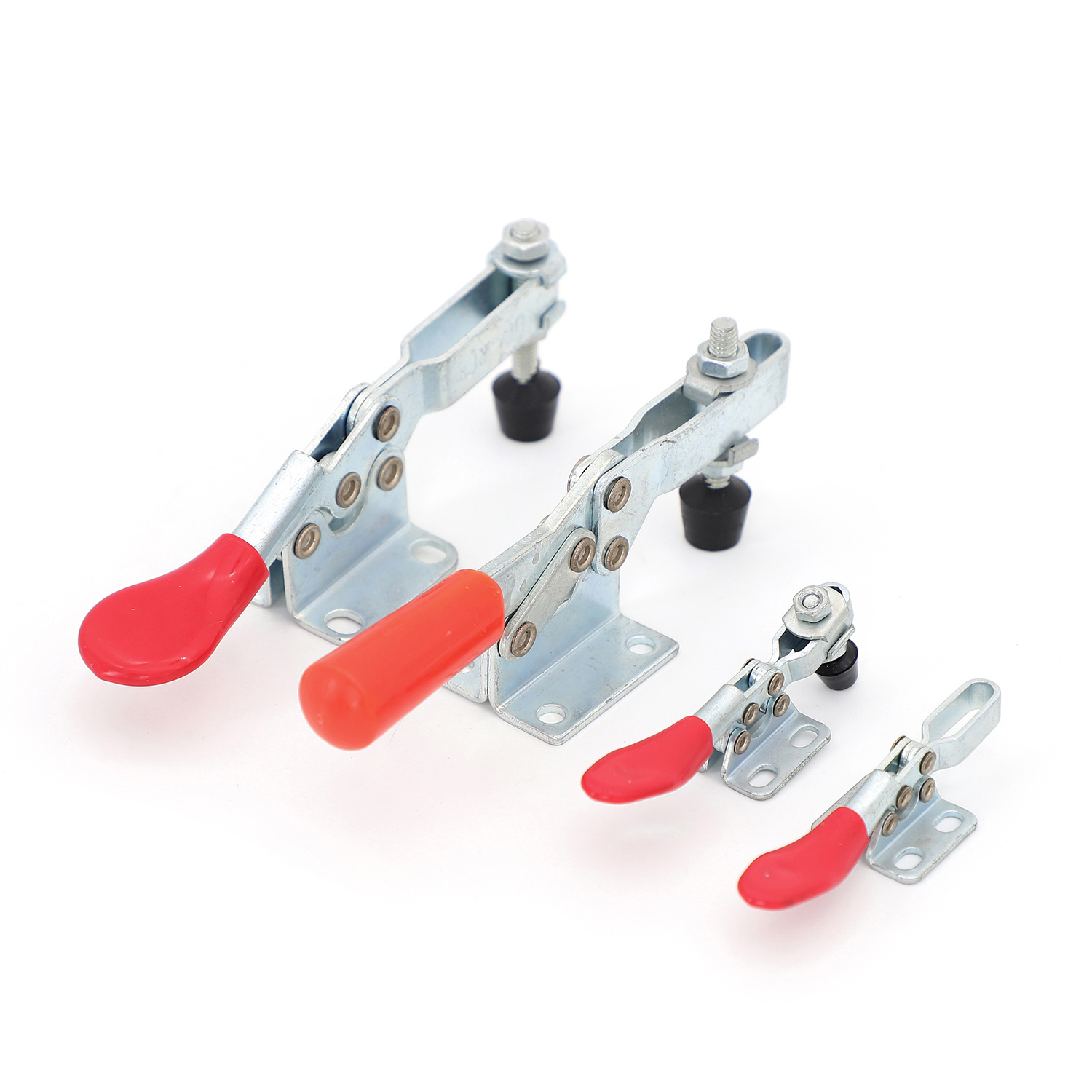

Toggle latch material and finish

Toggle latch material and finish

May .06.2022

Zinc Plated Iron

Nickle Plated Iron

Stainless Steel 304

Stainless Steel 316

Nickle Plated Iron

Stainless Steel 304

Stainless Steel 316

Deutsch

Deutsch  Français

Français  Español

Español  Русский

Русский  Português

Português